Accelerate development with simulation models

June 27, 2024

A lot of time passes before a functional prototype of a complex system is created, as the parameterization of all components has to be coordinated with a large number of suppliers. Behavioral models are used to simulate the interaction of the individual components in the digital machine twin under various framework conditions. Schreyer Sondermaschinen GmbH, a manufacturer of turnkey line systems and customized special machines, uses halstrup-walchers drive technology for format adjustment, including the digital twin, in the development project for the flow-wrapping machine.

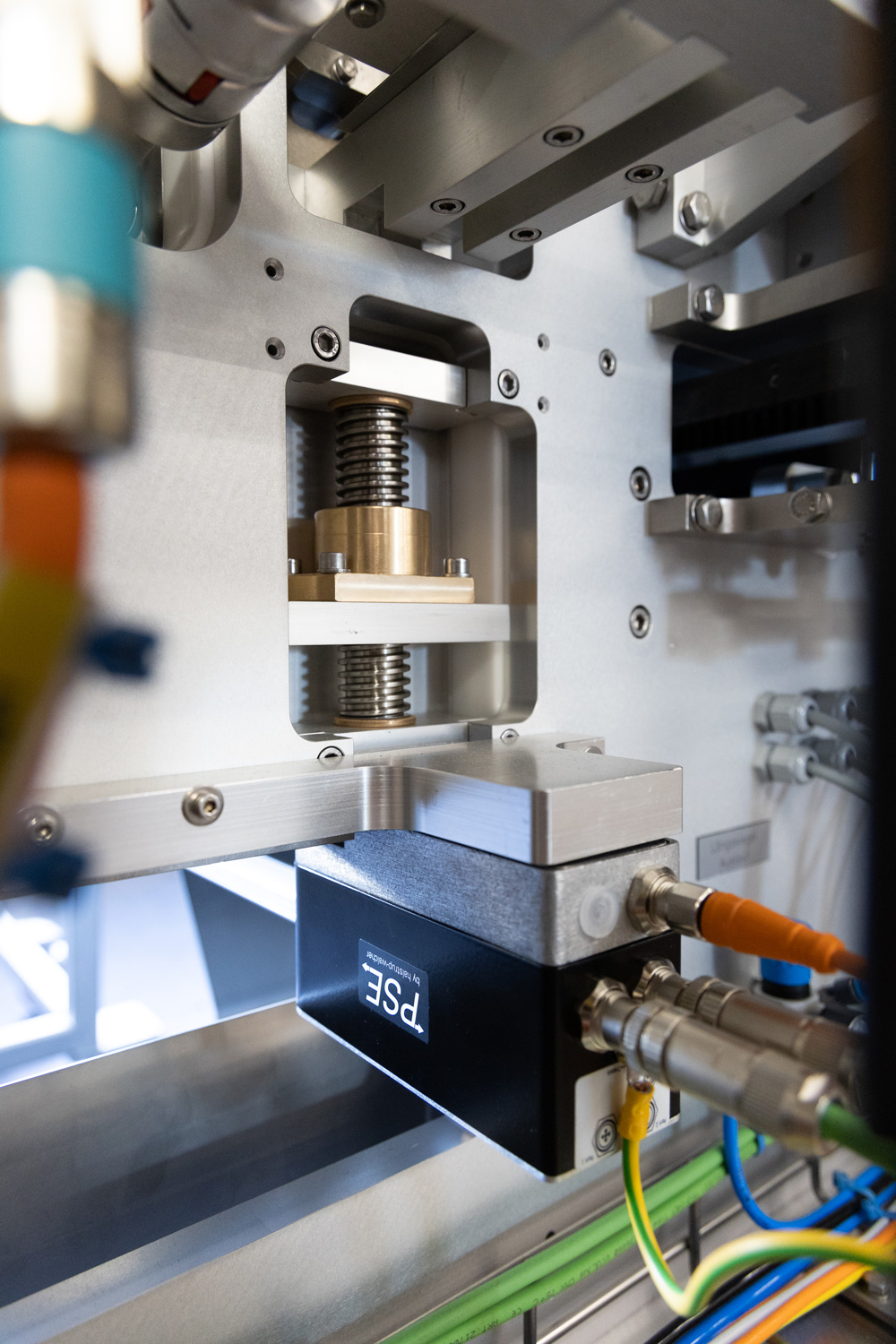

Automatic format adjustment of the transverse sealing station

Due to the increasing variety of products and formats that are packaged with the Schreyer flow-wrapping machine, regular height adjustment of the transverse sealing stations is required. The PSE3218-14 positioning system from halstrup-walcher has not only impressed in terms of performance and quality, but also in terms of its uncomplicated handling. Since the first PSE was used at Schreyer around eight years ago, there have been no technical problems or maintenance requirements.

Simple integration of the PSE behavior model into the digital machine twin

The “Functional Mockup Units” (FMU) provided by halstrup-walcher are the digital image of the positioning systems used in the machine. Together with the virtual HMI, the control software and the other simulation components, they form the digital twin of the machine design. The digital integration of a component as early as the development process can save a lot of time and therefore money. The FMUs from halstrup-walcher contain, for example, data for dimensioning the motor (including the status word and the behavior in the event of temperature changes or a drop in motor voltage), the procedure for the target position or the duration of the format adjustment. In addition to dimensioning during the development process, relevant machine states can also be simulated after development and important data on machine behavior under changing conditions can be collected.

Information about Schreyer Sondermaschinen GmbH

Uwe Schreyer is the second generation of his family to run the company. Under his leadership, the team of 25 employees develops and sells, for example, special tubular bags, stretch and carton packaging systems and electro-pneumatic high-speed distribution and unifying systems, which are used for lean packaging processes for ice cream and pizza, among other things.

Publications (German only)

Konstruktionspraxis:

packREPORT:

Digitaler Zwilling Schnellere Maschinenentwicklung (Printausgabe 4/2024)