Woodworking machines

Where our positioning systems are used: Format changeover in woodworking machines at Becherer Möbel-Innenausbau.

The fact that format changeover has become part of today's woodworking industry for a long time, can be seen very clearly in the example of edge banding machines. Anyone who supplies individual furniture with high quality demands is significantly helped by the automation of the adjustment axes. halstrup-walcher positioning systems have the task of implementing every format change to the next type of edge, precisely and quickly, and are absolute reliability. Becherer has been using a machine with format changeover for 10 years and is convinced by the precise adjustment and reliability.

The creation of modern interior designs with woodworking machines

Mention a woodworking business in the Black Forest to an architect, hotelier or house builder in a major city such as Frankfurt or Berlin and he will probably imagine an ancient workshop teaming with carpenters plying their humble trade with traditional tools.

The reality is quite different. Becherer Möbel-Innenausbau GmbH in Elzach is the perfect antidote to this outdated picture. Here, in a workspace covering an area of 4,000 m 2 , 45 highly motivated employees manufacture modern wooden furniture and interior furnishings. A handsome administration building completes the ensemble – and the adjacent logistics hall has even won an architectural award. Is this truly the home of a Black Forest carpenter?

Magnus Becherer and his cousin Benedikt are the fourth generation of the family to manage the company, together with Wendelin and Rochus from its third generation. Magnus willingly divulges the secret of the company’s success. “We have designed our business to provide precisely what our customers demand. They not only want boards cut to measure but also a reliable partner who supplies them with the products they need quickly, flexibly and punctually – and all with outstanding levels of quality and care.”

In other words, the company’s customers are sophisticated. In order to satisfy their high standards, Becherer employs its own interior designers and technical draughtsmen. It has also used CAD programs in every aspect of its design processes and modern CNC machines in its manufacturing for many years. The spacious production hall is home to a large number of highly automated woodworking machines made by the renowned manufacturer HOMAG. These are notable for both their robust and flexible design.

As well as CNC processing, one of the most important elements is the

edge banding machine. Each chipboard element, whether it is destined to become

part of a table, wardrobe, ceiling element or room divider, has cut edges which

must be covered with the appropriate veneer or solid wood edge banding. This

requires a remarkable degree of flexibility because, in many cases, only 3 or 5

pieces will receive the same type of edge banding before the machine has to be

adjusted yet again, e.g. from a narrow to a broad edge. In order to reduce

costs and the time needed for these adjustments, all HOMAG edge banding

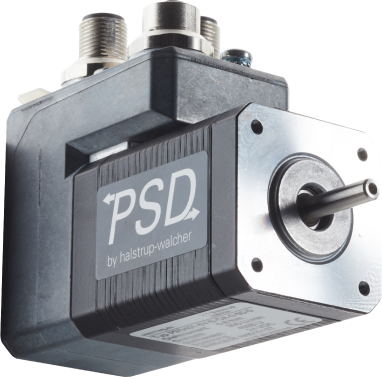

machines are fitted with “positioning systems” from halstrup-walcher.

These positioning systems are responsible for executing every format change to the next type of edge banding precisely and quickly. In practice, the machine operator simply inserts the new edge banding and enters the correct width measurement into the control panel. The mitre saw, the slitting knife and other tools move to the new horizontal and vertical positions in just a few seconds.

The machines never cease to amaze Magnus Becherer. “It is fascinating to see how such a large and powerful machine can operate with such extraordinary precision! For example, this HOMAG machine has been in operation here every day for over ten years without any unscheduled stoppages or significant problems. The PSE positioning systems from halstrup-walcher, in particular, are utterly reliable. These are the hard-working field components, which are the key to automating the machinery! Obviously, it is vital for us to avoid rejects and mistakes because the edge banding is often applied to parts that have already been processed using sophisticated and expensive techniques. However, we know that with HOMAG – and therefore also with halstrup-walcher – we are in the best hands!”

Magnus Becherer’s gaze wanders briefly with satisfaction around his inviting office. But he has little time to savour the view: his telephone rings. A customer has a few last minute changes to some measurements although the parts are due to be manufactured this very afternoon. Mr Becherer remains entirely relaxed – his company has the flexibility to cope with last minute alterations like these with ease! It is all a matter of the right position. And, last but not least, the right equipment!

Our drives

We are specialists for individual positioning systems and drive solutions.

Get to know our product variety.